Manufacturing Evolution Over Last Five Years

The manufacturing industry has undergone significant transformation over the past five years, marked by technological advancements, shifting global dynamics, and evolving consumer preferences. From the rise of Industry 4.0 to the challenges posed by geopolitical uncertainties and the COVID-19 pandemic, manufacturers have navigated a rapidly changing landscape. In this blog, we delve into key trends and developments that have shaped the manufacturing sector over the last half-decade, highlighting both challenges and opportunities that have emerged.

Embrace of Industry 4.0 Technologies

The past five years have witnessed a widespread adoption of Industry 4.0 technologies across the manufacturing sector. From advanced robotics and automation to Internet of Things (IoT) devices and artificial intelligence (AI), manufacturers have embraced digital transformation to enhance efficiency, productivity, and flexibility. Smart factories equipped with interconnected systems and data analytics capabilities have revolutionized production processes, enabling real-time monitoring, predictive maintenance, and agile manufacturing.

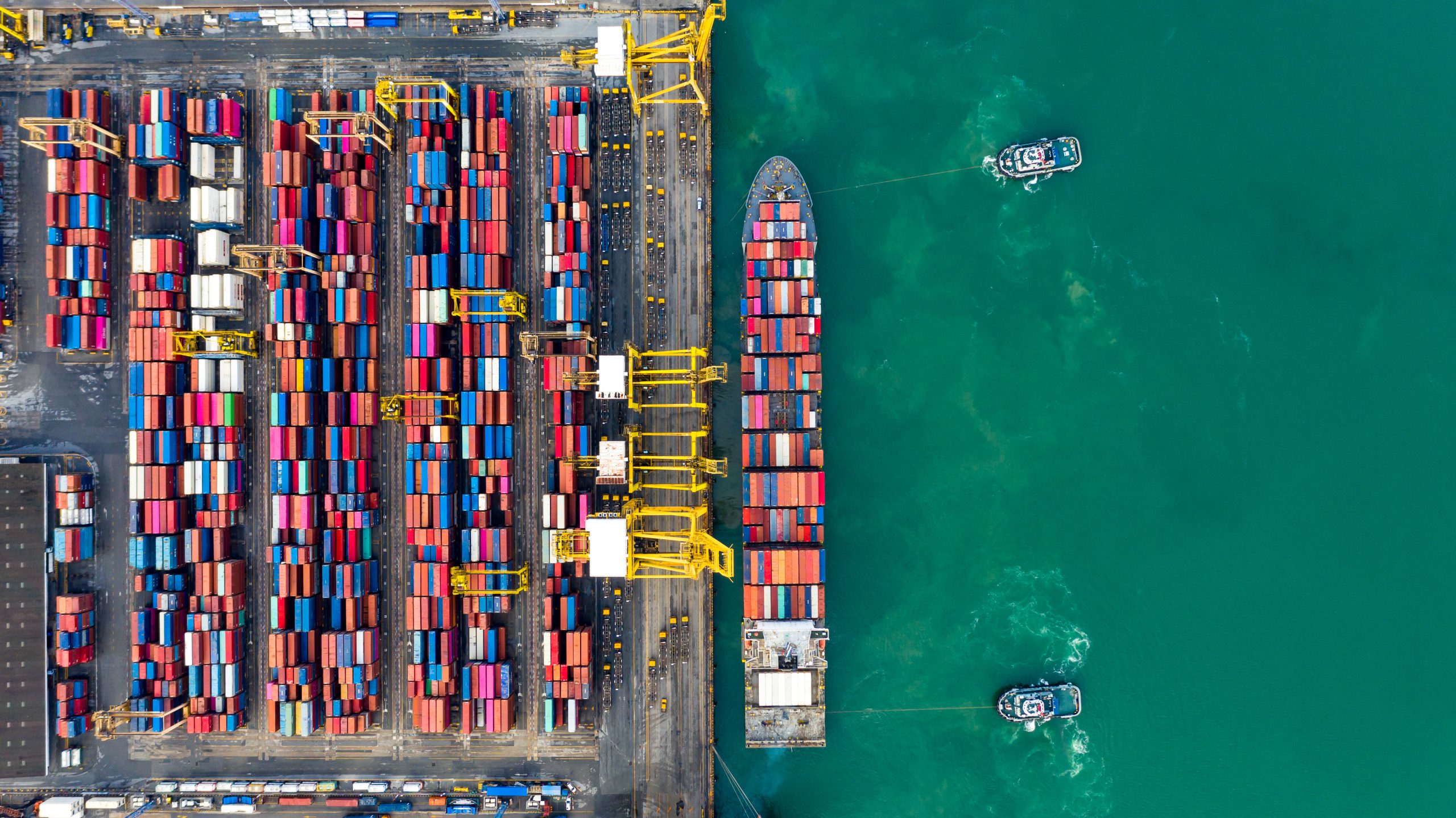

Reshoring and Supply Chain Resilience

The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting many manufacturers to reconsider their sourcing strategies. Over the last five years, there has been a trend towards reshoring and nearshoring as companies seek to mitigate risks associated with disruptions and strengthen post-pandemic supply chains. Building resilience into supply chains through diversification, localization, and closer collaboration with suppliers has become a priority for manufacturers looking to enhance agility and responsiveness to market fluctuations.

Sustainability and Circular Economy

Environmental sustainability has emerged as a key focus area for the manufacturing industry in recent years. With increasing awareness of climate change and resource scarcity, manufacturers are embracing sustainable practices to minimize environmental impact and meet regulatory requirements. The concept of the circular economy, which aims to reduce waste and maximize resource efficiency through recycling and reuse, has gained traction within the manufacturing sector. Companies are investing in eco-friendly technologies such as heat induction bending services, renewable energy sources, and closed-loop systems to minimize waste generation and carbon emissions.

Resilience Amidst Disruptions

The manufacturing industry has faced numerous disruptions over the past five years, including trade tensions, natural disasters, and the COVID-19 pandemic. These disruptions have underscored the importance of resilience and adaptability in manufacturing operations. Heavy steel fabrication companies that have invested in digitalization, supply chain visibility, and risk management have been better equipped to weather the storm and pivot swiftly in response to changing market conditions. The ability to anticipate and mitigate risks will continue to be critical for manufacturers in the years ahead.

Skills Gap and Workforce Development

As manufacturing becomes increasingly digitized and automated, there is a growing need for a skilled workforce capable of leveraging advanced technologies. However, a widening skills gap has been a challenge facing the metal fabrication industry, with shortages of workers trained in STEM (science, technology, engineering, and mathematics) disciplines and digital skills. Over the last five years, manufacturers have ramped up efforts to address this challenge through investments in workforce training, apprenticeship programs, and partnerships with educational institutions. Building a talent pipeline equipped for the demands of modern manufacturing will be essential for future growth and innovation.

Closing Comments

The past five years have been transformative for the manufacturing industry, characterized by technological innovation, supply chain disruptions, and a heightened focus on sustainability and resilience. As manufacturers navigate the challenges and opportunities of a rapidly evolving landscape, adaptability, agility, and forward-thinking will be key to driving success in the years to come. By embracing digitalization, prioritizing sustainability, and investing in talent development, manufacturers can position themselves for continued growth and competitiveness in an ever-changing global marketplace.