Applications of Titanium in the Fabrication Industry

When the word “Titanium” is used or comes to mind, the immediate connotation is of a high-quality metal utilized in NASA spacecraft and other cutting-edge technology. A fun fact about titanium is that it is the seventh most common metal and the ninth most common element in the universe. It is also prohibitively expensive, due to the difficulties involved in extracting the metal for industrial use. Titanium also has a variety of uses in metal and structural steel fabrication which leverages its remarkable characteristics. This blog will discuss in more detail as to how titanium is playing a major role in multiple industries.

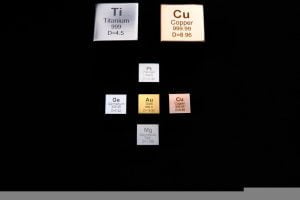

Titanium Features – Evoking “The Titans”

Titanium possesses incredible tensile strength. It is as strong and light-weight as steel, however it is 45% lighter and more durable than aluminum. Even though it is 60% heavier, it has a tensile strength two times greater than aluminum. Titanium is resistant to oxidation in sea water and has a melting point of 3,034°F, making it resistant to extreme temperatures (1,668°C) and useful for heat induction bending services. Even at high flow rates, it still holds up against abrasion, cavitation and erosion. Only titanium alloys can be made at very high temperatures and in vacuums. Hence it is observed that it is worth more per ounce than iron. Titanium is found in ilmenite (iron-titanium oxide, FeTiO3) and rutile (iron-titanium oxide, FeTiO2) (a titanium oxide, TiO2). China contains the greatest ilmenite, but Australia has the largest worldwide rutile concentration, at roughly 40%, according to Geoscience Australia. Ilmenite is most prevalent in China. It may be found mostly throughout Australia’s east, west, and southern coasts.

Applications in Aerospace

Titanium is 30% stronger than steel yet weighs half as much, making it an excellent choice for the aerospace sector. Aircraft designers seeking to create quicker, lighter, and more efficient aircraft are increasingly turning to titanium as a go-to material as it is suitable for cutting, shaping and folding operations. Titanium accounts for 39% of the F22 Raptor, the most modern fighter aircraft in the world, manufactured by the United States Air Force. The new Boeing 787 Dreamliner, which is substantially more titanium-intensive than earlier models, represents a similar step forward in civil aviation. Titanium is used extensively in the landing gear and jet engines of commercial aircraft. A plane’s landing gear is subjected to a tremendous amount of stress when it strikes a runway. This leads to generation of enormous quantities of energy; titanium can absorb such energy without ever degrading. Modern jet engines, which can achieve temperatures of up to 800°C, may benefit from titanium’s heat resistance. Titanium can tolerate the heat of a jet engine without compromising its structural integrity at roughly 400°C.

Applications in Replacement of Body Parts

Due to its resistance to corrosion by human fluids, titanium is regarded the most biocompatible metal – one that is neither hazardous or poisonous to living tissue. When oxygen is present, a protective oxide coating formed that shields our bodies from the damaging effects of our environment. Titanium has an advantage over other materials in that it does not need the usage of an adhesive to stay connected. It takes far more force to break the links between titanium implants and the human body compared to their alternatives.

Dental implants, dental crowns, and cranioplasty plates with titanium may all be made using 3D printing technology. Along with automation in the fabrication industry, this is a game changer for titanium because of the low-cost accuracy of 3D printing. Layer by layer, 3D printing allows designers to build incredible forms. New titanium-based 3D printing technologies are being developed in collaboration with industry.

Concluding Statements

Apart from the above, titanium is used in sports equipment, automobiles, jewelry and pipelines and industrial equipment. Hence, the usage of titanium can help to resolve many of the challenges being faced by the metal fabrication industry. It is also connected with high-end technology as an investment. As a result, the market for this high-tech metal is expected to grow in the coming days. Many industries are starting to consider titanium as the new steel – and they are not far off the mark!