Potential Benefits of Augmented Reality in Manufacturing

It is no secret that Australian manufacturers and fabricators have been facing enormous challenges over the last few years. This includes tackling a widespread skills gap, experiencing difficulties in finding skilled workers despite job vacancies in Australia peaking at a record 480,900 positions in 2022, managing an ageing workforce with projections that around 40% of the workforce will be over 55 by 2050 and the loss of important skills as older workers head towards retirement. To mitigate these challenges, manufacturers must take their digital transformation to the next level and embrace intelligent technology such as augmented reality (AR) to better support frontline workers. How does AR make manufacturers’ lives better? Let us find out further in this blog.

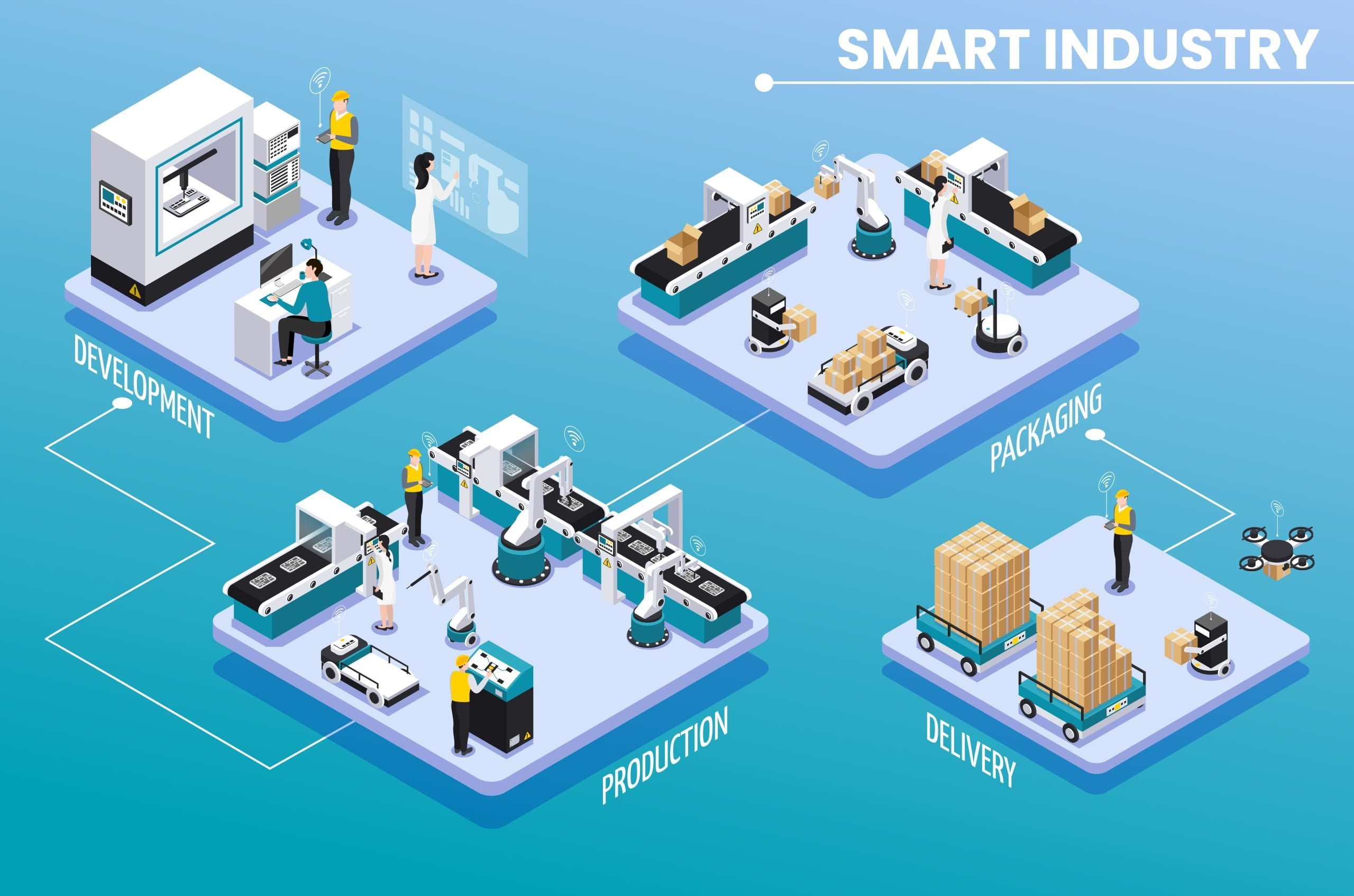

Industry 4.0 and the smart factory

Industry 4.0 has delivered advances such as robotics in the oil and gas industry, artificial intelligence (AI), AR, and virtual reality (VR). With the rise of the smart factory, technologies such as AR will be the driving force behind increased profitability, better quality goods, and faster production. Already, many enterprises are benefitting from AR through quality control, maintenance, and repair, streamlined workflows, and remote onboarding and training, to improve productivity, enhance safety, and tackle the skills gap. There is incredible potential for AR to be deployed to support frontline workers on factory floors, from manufacturing to food and beverage packaging. AR can equip frontline staff with digitized manufacturing processes through ‘smart glasses.’ These glasses can replace error-prone paper lists or manuals and enable smoothly guided assembly. They ensure the user always has all relevant information in view, and both hands free for their current activity. AR-enabled cameras and sensors can also provide a standard quality assurance system that ensures perfect results in each production step.

AR in action

Users showcase how AR streamlines frontline activities in warehouses and on factory floors of heavy steel fabrication companies. Global soft drink giant Coca-Cola Hellenic Bottling Company (HBC) switched to smart glasses and remote assistance from TeamViewer to improve picking quality and pallet packing accuracy in its warehouse. Using smart glasses, Coca-Cola’s employees at any of its 54 locations can contact experts remotely via video call and get help to restore operations with a minimum of downtime. Management visits and training can now also be carried out remotely over video calls, streamlining and extending the transfer of skills. However, the real value of AR is that it can be deployed anywhere, anytime, to solve multiple challenges. Both Toyota and BMW use AR in the field to help their technicians work more efficiently and effectively to get customers back into their vehicles sooner. Using AR, technicians can contact experts directly through their smart glasses. The camera in the smart glasses captures the mechanic’s exact field of view and the image is transmitted to a remote expert through a video call in real time. The expert assesses the situation, offers technical advice, and helps solve problems efficiently and collaboratively. Parts of the vehicle’s assembly instructions, including pipe fabrication components, can also be displayed directly in the technician’s field of vision on-site, or instructions can be visually clarified using remote support features. While this improves customer service, it also means that technical support engineers can help far more in-field technicians without wasting a large amount of time on the road.

Closing Thoughts

With Industry 4.0 now commonplace, it is time for Australian manufacturers to move forward and invest in solutions such as AR to help deliver exceptional experiences for their frontline staff. AR lets manufacturers better support their staff while simultaneously improving productivity, tackling skills gaps, and minimizing errors. The AR train is starting its journey and manufacturers need to hop on at the earliest!