Utility of Punch Press Machine

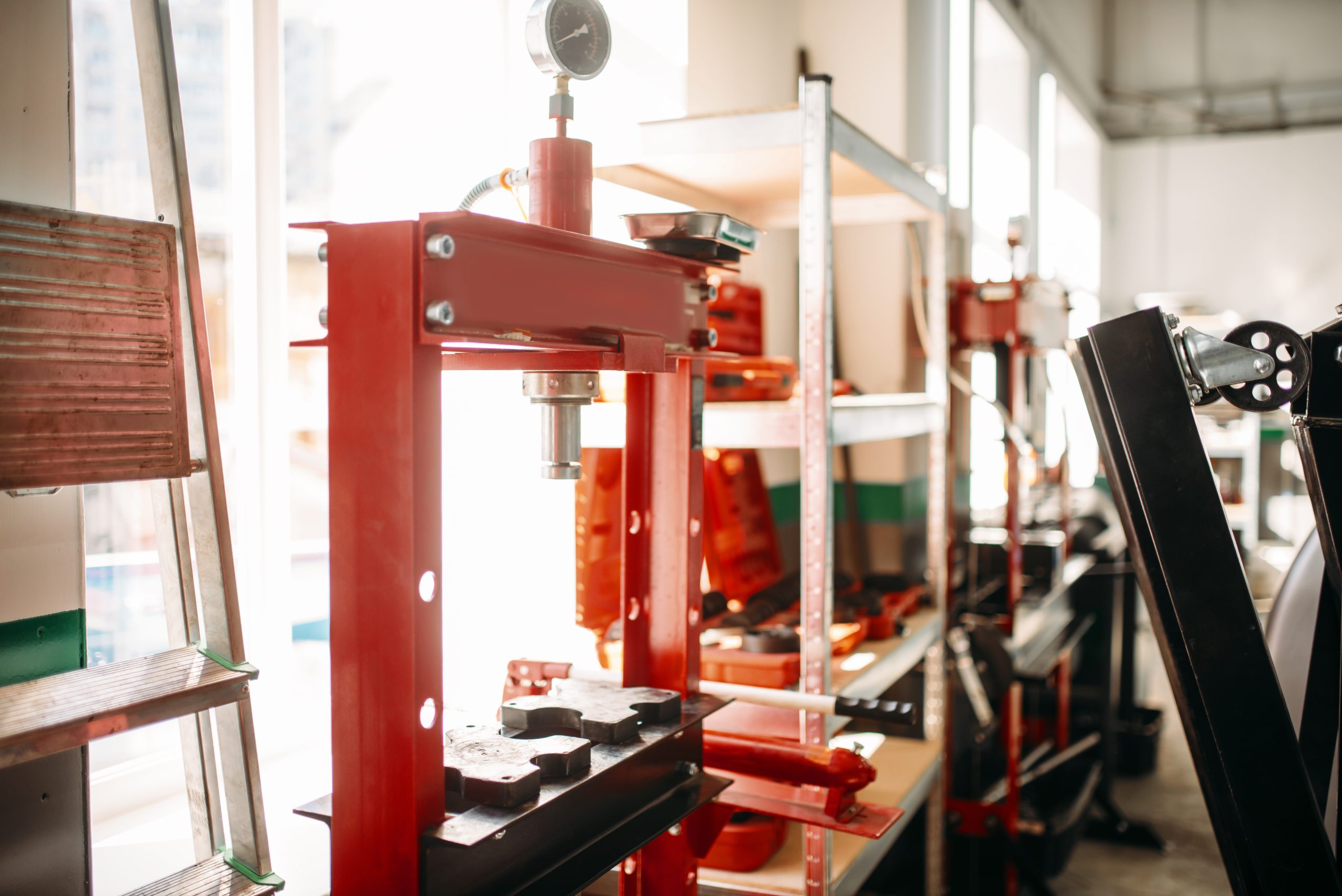

Punch presses are one of several equipment used by manufacturers and heavy steel fabrication companies to manipulate and convert raw materials into finished products. Making uniform shapes out of raw material in large quantities is much easier with the use of punch presses. A punch press may be used by a company if a specific raw material is too difficult to cut manually since it cuts through metal and other hard materials with ease, creating holes that match the die form of the punch press. So, what are the applications and utilities of punch presses? This blog will look to explore this topic in further details.

Types and Applications of Punch Press

Similar to press brake machines, punch presses are used in stamping, punching, bending, shearing, converting, and assembly operations. They differ in terms of drive type and automation. Air-driven punch presses are powered by a pneumatic cylinder and are suitable for light-duty applications. Hydraulic presses are powered by a fluid-filled cylinder and can generate extremely strong forces to form metals and other materials. Manual presses are driven by hand, or powered with manual force that is magnified by a screw, lever, or other mechanism. Mechanical punch presses are driven by a rotary motor and screw, toggle, or lever. By contrast, servo-controlled presses are driven directly by a servo motor. Some punch presses are controlled manually, using operator interface devices such as footswitches, pendants, or push button controls. Others include a computer numeric controller (CNC) or programmable logic controller (PLC). Punch presses that are programmed and controlled with a personal computer (PC) interface allow users to set and adjust parameters such as speed and applied load. Indexing machines are fully automatic and can load parts and adjust parameters without operator intervention.

Specifications of Punch Press

Important specifications for punch presses include operating force, rated capacity, production rate, and sheet capacity. Operating force is the maximum load required to cut or form parts during assembly. Rated capacity is the tons of pressure via pressure vessels that the slide or ram exerts at the bottom of the stroke while working within the range of the press. With mechanical punch presses, operating force is a function of the bending capacity of the main shaft. For all types of punch presses, production rate is the number of operations performed or units produced per unit of time. Typically, this amount is expressed as the number of strokes, hits, cut-outs, cycles, or hits per minute. Most manufacturers specify sheet capacity in terms of maximum thickness, working length, and working depth. Working length is the maximum sheet length (largest dimension, X) or working distance from right to lift that can be punched, formed, or converted. Working depth is the maximum sheet (smallest dimension, Y) or working depth from front to back that can be punched, formed, or converted.

Special Features of Punch Press

Punch presses are available with a variety of special features. Some machines include integral shearing capabilities or optional material feeders. Others include laser cutting or monitoring systems. Multi-station punch presses include rotary tools and turrets, progressive dies, transfer systems, or multi-tool die sits. Rotary punch presses index materials and allow operators to select an appropriate tool from the turret. Loading and stacking systems are complete manufacturing cells that often include material handling and degreasing subsystems. They provide sheet, part, and material handling.

Closing Thoughts

Punch presses have a multitude of applications and they are versatile in their use throughout industry. In fabrication, punch presses provide a viable alternative to metal cutting and can also provide a degree of automation with certain types of punch presses. Going forward, it can be safely concluded that punch presses will continue to “punch” above their weight in the metal work world!